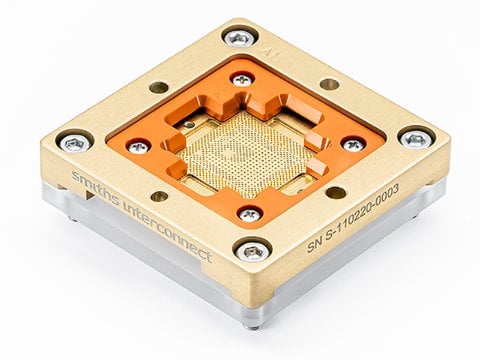

- Fine pitch applications

- Quad-0 and Quad-00 Series probes and receptacles

- Between 0.30 and 0.50 A current ratings

- 0.70 to 0.75 oz. spring forces

- ≤ 0.900" (22.86 mm) overall lengths

- IDI Spring Probe technology

| Probe | Probe OAL |

Max Travel |

Mating Receptacle |

|---|---|---|---|

| Quad-00 Series |

0.740 (18.80) |

0.100 (2.54) |

Quad-00 Series |

| Quad-0 Series |

0.900 (22.86) |

0.100 (2.54) |

Quad-0 Series |