- Low RF noise and high durability over 500 mating cycles

- Offered with 100 ohm quadrax or twinax contacts

- Higher bandwidth support up to 6.25 Gbps

- Meet MIL-STD-202 requirements for shock and vibration

- Optimized impedance matching for signal integrity

- Size 10 contacts are 30% smaller package size for tight space constraints

- Cable assembly options available

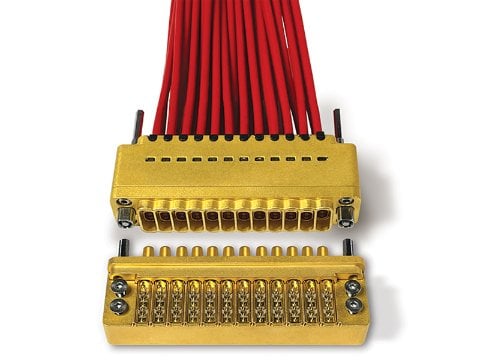

Our D-Sub meets and surpasses all requirements of MIL-STD-202 for shock and vibration, and is offered with 100 ohm quadrax and/or differential pair twinax contacts. To ensure that the correct high speed connectors are mated to address specific wiring requirements and keying combinations, a keyed jack post was incorporated into the design. The six-positioned keyed jack post allows for 36 possible keying combinations assuring that the correct high speed rugged D-sub plug is mated to the correct high speed receptacle.