- Available in 0.40 mm, 0.50 mm, 0.65 mm, 0.80 mm, and 1.00 mm pitches

- Custom pitches down to 0.30 mm

- Lidded and Open Top Sockets for ≤10 mm packages

- Lidded Sockets for 10 mm to 16 mm packages

- Center ground pin standard for all sockets

- Optional copper heat slug available for high wattage devices

- Sockets for over 80 different JEDEC standard footprints

-

Custom Connectors VS Catalog Connectors: Benefit Breakdown and Challenges

There's no escaping the expectations to create more compact electronic components with higher functionality. Designing shrinking electronics is a challenge for all electronics manufacturers. Whatever industry you're in and no matter if you’re creating consumer, business, or military-grade electronics, there is a demand for building smaller, smarter, and sturdier electronics.

-

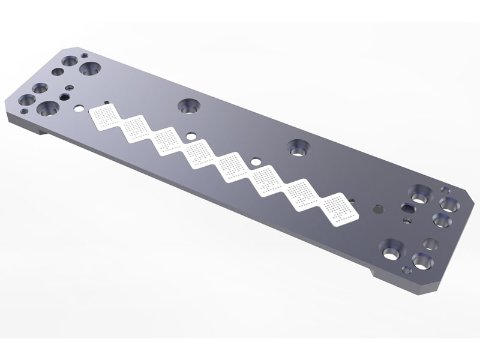

New Volta 180 supports Wafer Level Packages and Known Good Dies test businesses

The new Volta 180 Series is an advanced WLCSP test solution that expands Volta product line to include the compact 180um pitch, allowing for a higher number of chips to be tested on each wafer. It allows for a fast and reliable testing of wafers to ensure that they meet specifications and perform as they should, which translates into higher quality end products.

-

Rethinking Blind Mate Connectors to Increase Reliability in Miniaturized Electronics Assembly

Creating more compact electronic components with higher functionality is a challenge for all electronics manufacturers. Whatever industry you're in, creating consumer, business, or military-grade electronics, the challenge presents itself, and the stakes are high. As electronics are expected to continue shrinking while increasing capabilities, blind mating connectors are required to meet those same size and functionality requirements.

-

High-Power Burn-In Testing in 2023: How to Overcome the Extreme

The tech zeitgeist is all about the extreme. The more advanced our devices become by the day, the more they evolve – and consumers’ expectations with them.