The global automotive industry advances rapidly toward fully autonomous (Level 5) vehicles. Today, many competing data gathering fleets of vehicles are logging millions of km on the roads of the world in order to amass the data required to feed and train the AI that will enable full vehicle autonomy. The detection accuracy and the size of the dataset demanded by those safety-critical training systems is very high, as is the bandwidth, performance, and reliability of the high-speed links providing the data collecting backbone of these vehicles.

The Application

The data gathering systems used in those vehicles are expected to operate flawlessly irrespective of weather conditions, visibility, or road surface in order to improve data quality and accuracy.

Training a roadworthy algorithm

Neural networks need to be trained on representative datasets that include examples of all possible driving, weather, and situational conditions to ensure reliable, flawless operation of the future self-driving vehicles.

Gathering data

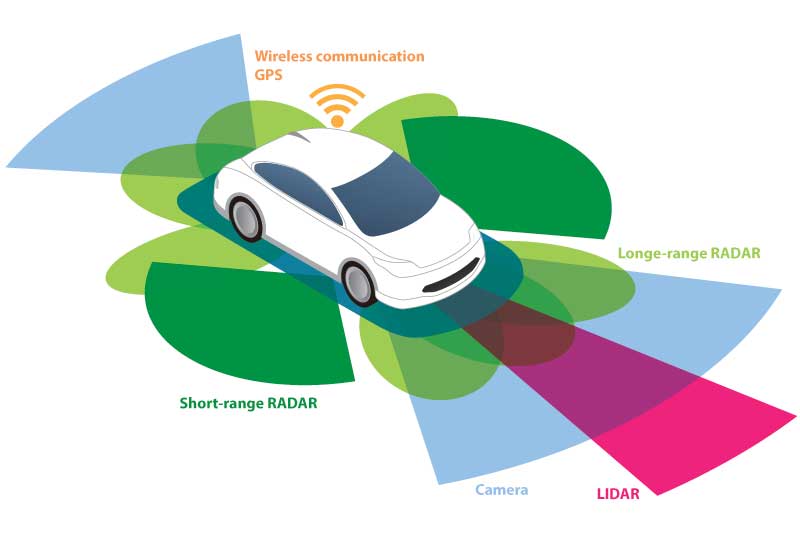

In order to amass as much driving environment data as possible, a typical data-gathering vehicle setup consists of a multitude of sensors including cameras, radar and lidar, giving the vehicle 360-degree data gathering capability. In practice this translates into petabytes of training data being shuttled from sensors, to computer, to storage over the vehicle’s high-speed, hight-bandwidth data collection networks.

Obviously, the exact instrumentation details of specific manufacturers or suppliers are not in the public domain. But one can reasonably assume that the amount of data generated and the speed at which it is generated demand a very robust and high-bandwidth system.

High bandwidth needs calls for optical

The data collection network and computing systems of these vehicles are expected to:

- Connect LIDAR and radars.

- Connect high-resolution cameras.

- Provide centralized processing power and storage.

- Operate in harsh environments.

Eliminating the network bottleneck

By offering much higher speed that what is available with copper interconnects, optic fiber data links remove the bottleneck in the data collection network and enable high-quality uncompressed data to be stored in the vehicle.

Benefits of using LightVISION VM industrial optical transceivers

- Bandwidth from 40G (4 TX or 4 RX lane) to 120G (12 TX or 12 RX lane)

- Lightweight and easy to integrate optical cable

- Multimode 850 nm wavelength laser

- Standard MPO parallel fiber connector.

- Available in commercial (0 ºC to 70 ºC) and industrial (–40 ºC to 100 ºC) grade temperature ranges.

- Suitable for harsh environment and automotive applications

- Standard MTP/MPO cable connection

- RoHS, robust, screw-in board-mounted optical module with reduced footprint

- Low power consumption: <100 mW per lane

- Over 100 m reach on OM3 ribbon fiber

Data recording and reinjection for ECU validation

The SLA is a high-precision SerDes scenarios and RADAR data-logging and replay solution to enable your testing and validation activities for the development of advanced driver-assistance systems and automated driving functions.

- Automotive grade system ready for in-vehicle use and HiL systems

- Transparent video and radar SerDes data logging including sideband information of GMSL2 and FPD-LINK-III links.

- Streaming of logged data through 10Gbits Ethernet interfaces. Compatible with every Ethernet storage system.

- High precision time stamping including external synchronization to IEEE802.1AS master clock

- Optional real time data compression

- Optional replay function to enable HIL data reinjection and reprocessing

- Optional ECU debug extension to log ECUs internal interfaces.

- Small size factor for easy in-vehicle integration