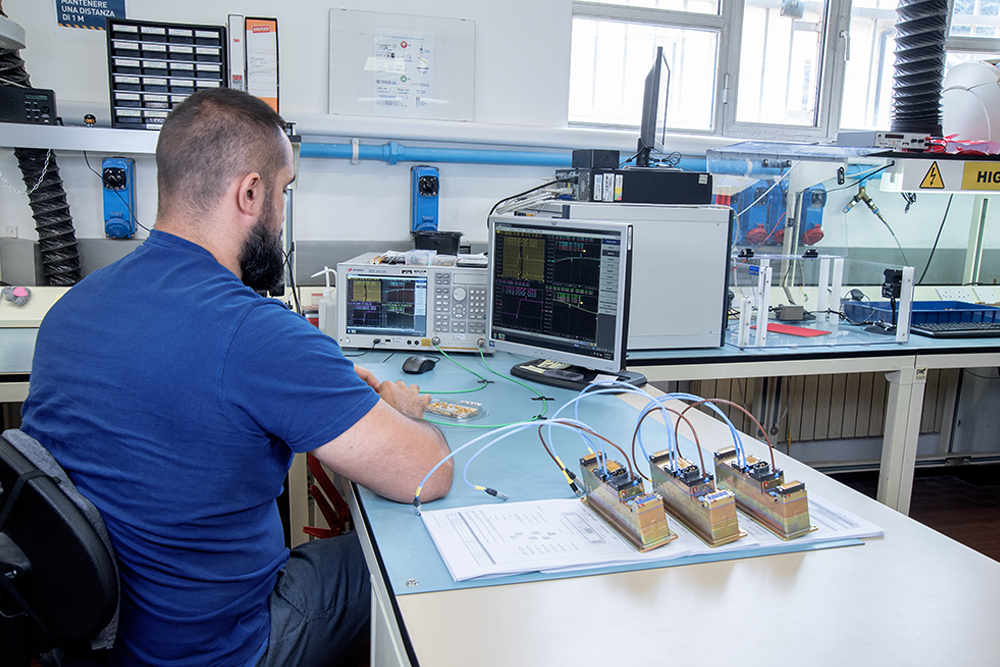

Smiths Interconnect’s in-house capabilities encompass design, development, manufacturing, and testing to respond quickly and accurately to customers’ needs and provide the most reliable connectivity solutions.

-

Engineering

- 3D EM Modelling

- Advanced RF & System Modelling

- CAD/CAM & Solid Modelling

- Finite Element Analysis

- Thermal Analysis

- Shock & Vibration Analysis

- Reliability Analysis

-

Manufacturing

- Precision Machine Shops

- Connector, Contact, & Cable Assembly

- Automated PCB Assembly & Inspection

- Automated Hybrid Assembly

- Die Placement

- Wedge & Wire Bonding

- Gap Welding

- NASA-Certified Soldering

- Automated Test & Tune

- System Integration

- Validation Testing

-

Prototyping

- CNC turning and milling centers

- Cabling / Prototype Assembly

- 3D Printing

- Ceramic Grinding

- EDM

- Circuit Board Routing

-

Testing/Qualification

- Electrical Acceptance & LOT Test

- RF Test Capability, up to 110 GHz

- High Speed Digital

- Anechoic Chamber Testing

- ESS Environmental Qualification

- ESS Temperature, Shock & Vibration

- Metallurgical

- Real Time X-Ray

- Near Field/Compact Antenna Range

- Thermal Vacuum

- High Power RF Testing

- Optics Lab

- Multi paction, SRS mechanical shock