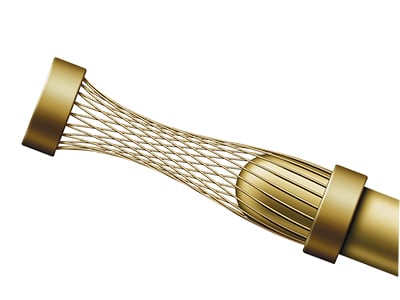

Hypertac® is an advanced hyperboloid contact technology that satisfies the most demanding performance requirements. The shape of the contact sleeve is formed by hyperbolically arranged contact wires, which align themselves elastically as contact lines around the pin, providing a number of linear contact paths.

The smallest practical pin diameter is 0.3mm but there is effectively no upper limit. The superior design of the Hypertac® contact system offers exceptional performance features:

Low insertion/ extraction forces

The controlled angle of the socket wires allows tight control of the pin insertion and extraction forces. The spring wires are smoothly deflected to make line contact with the pin.

Long contact life

The smooth and light wiping action minimizes wear on the contact surfaces. Hypertac® contacts perform up to 100,000 insertion/extraction cycles with no degradation in performance.

Tests have been successfully concluded as follows:

- 500 insertion and withdrawals followed by 1000 hours at 125°C, multiple exposure to salt mist, or 21 days exposure to sulphur dioxide

- 20,000 full insertion and withdrawal cycles in a benign environment

- Over 10 million fretting cycles of approximately 1mm movement

The Hypertac® contact has been monitored for circuit interrupt of greater than 2 Nano-seconds and has successfully past all tests.

Lower contact resistance

Hypertac® multiple line contacts provide far greater contact area than other contacts of comparable size. The wiping action of wires insures a clean and polished contact surface. Tests have shown Hypertac contacts have about half the resistance of conventional contact designs.

Higher current ratings

The design parameters of the Hypertac® contact may be modified for any special requirement. For example, the number of wires can be increased in order to distribute the contact area a larger surface of mating pin. Thus, the high current carried by each wire because of its intimate line contact, can be multiplied many times.

In addition, low contact resistance in high current application minimizes temperature rise thereby enabling higher density interconnects.

Temperature

The very low contact resistance of the Hypertac® socket ensures the minimum temperature rise at high currents. Peak temperature of insulator material is the primary limiting factor. Materials used in Hypertac® connectors chosen to:

- Provide widest ambient temperature range,

- Withstand temperature peaks during assembly, even those generated during vapor phase soldering.

Immunity to shock & vibration

The low mass and low inertia of the wires enable them to follow the most abrupt or extreme excursions of the pin without the loss of contact. The contact area extends 360° around the pin and is uniform over its entire length. The 3 dimensional symmetry of the Hypertac® contact design guarantees electrical continuity regardless of the direction or intensity of external or internal forces

Hypertac contacts and connectors have been tested to;

- Sine vibrations (according to CEI 68-2-6): 20 g from 10 to 2,000 Hz,

- Random vibrations (according to CEI 68-2-35): 0.5 g² / Hz from 10 to 2,000 Hz,

- Shocks (according to CEI 68-2-27): 250 g during 0.4 ms (1/2 sine-wave)

The results of all the tests carried out on Hypertac contacts have shown:

- No discontinuity when measured down to 2ns,

- A stable contact resistance.

The Hypertac contact guarantees the best performances in harsher environments.

Fretting Corrosion

Fretting corrosion is a contact failure mode of mechanically high stressed electrical contacts which causes unacceptable increase of contact resistance. It occurs when 2 contact surfaces are in relative small amplitude movements caused by external vibrations or temperature variations.

Hypertac’s solution to limit fretting corrosion:

- Plating: use no oxidized plating such gold,

- Reduce roughness,

- Use lubrication to reduce mechanical wear and degradation and prevent contact from oxidation by sealing it,

- Increase forces.

Compliant Materials

The design of the Hypertac contact is compliant with major international regulations:

- UL94V0 (self extinguished),

- I classification (oxygen index and glow wire test) and F classification (smoke toxicity and opacity) ,

- No PBB/PBDE flame retardants (RoHS),

- No asbestos,

- RoHS compliant platings.

In the increasingly harsh environments of several markets, Hypertac contact technology guarantees offers materials and plating’s that comply with human health, environmental and ecological regulations.

Hypertac Contact Benchmark

Hypertac® hyperboloid contact provides the following commercial benefits:

High density interconnect systems

Significant reduction in size and weight of sub-system designs can be achieved by employing Hypertac high density connectors with a large number of contacts that do not require additional hardware to overcome mating and un-mating forces

Low cost of ownership

Hypertac® Hyperboloid is ideal for applications that require frequent connector mating cycles, thus eliminating the burden and cost of having to replace the connector of the entire subsystem.

Low power consumption

The lower contact resistance of the Hypertac® contact results in a lower voltage drop across the connector which reduces the power consumption and heat generation within the system.

Maximum contact performance

The lower contact resistance of the Hypertac® reduces heat build up; therefore Hypertac contacts are able to handle far greater current in smaller contact assemblies without the detrimental effects of high temperature.

Reliability under harsh environmental conditions

Harsh environmental conditions require connectors that will sustain their electrical integrity even under the most demanding conditions such as shock and vibration. Hypertac provides unmatched stability in demanding environments when failure is not an option

We will be pleased to advise on your application and installation requirements. Hypertac® contacts can provide the solution to your interconnection needs.

HYPERBOLOID CONTACT STAMPED, HCS™

Description

The hyperboloid Contact Stamped HCSTM contact is the advanced evolution of the machined HYPERTAC® hyperboliod contact tcechnology.The uncompromising realization of the demands for even more low cost and fully automatic processability, based on the identically hyperboloid contact principle and performance, led Smiths Interconnect to the development of the stamped/rolled HCSTM contact.

Features and Benefits:

- Favorable price and reduced processing costs

- Fully automatic processable and reduced assembly time

- High reliability wire B-crimp and additionally insulation O-Crimp

- Compatible with all round pins in case of fitting diameters

The System

For all variations, the wire cage has the same design characteristics. In the contact area all single contact flaps are made in a circle shape which guarantees “wire quality”.

The HCS™ contacts, on reels for crimping machines with automatic feeder lines are fully compatible with our turned HYPERTAC® hyperboloid contacts. They are available in Ø 0.8/1.0/2.0 mm.

Smiths Interconnect offers a full service for crimping tools:

- Applicators for all typical crimp devices

- Smiths Interconnect offers hand crimp tools and positioners for field installation of our crimp contacts

Specifications

Electrical Load

Derating curve 100% acc. to DIN IEC 512/T3 (in air)

Vibration test per DIN EN 60512/item4, 35g X/Y/Z sinusoidal for 50h each, without discontinuities and without any change in contact resistance [<5mOhm].

TORTAC®

Boasting the same unique characteristics of the HC contact, on equal pin diameter the Tortac® socket features a smaller pitch that allows for a higher contact density. The reduced gap between the external and internal diameter of the socket guarantees a dramatically improved performance in high frequency environments and a steadier interconnection continuity profile.

- Miniature (higher - same mechanical and electrical properties of Hypertac contact)

- High reliability, high resistance to salt spray

- High signal speed thanks to the contact geometry

- Self cleaning

- 10,000 mating cycles