Smiths Interconnect announced the release of its SpaceNXTTM K2TVA Thermopad® Temperature Variable Attenuator for gain compensation over temperature.

Specifically designed and tested for critical space flight applications, the new SpaceNXT K2TVA series offers a highly reliable, totally passive solution to offset signal strength fluctuation due to changes in temperature – an issue that affects all RF and microwave systems. The attenuation shift over temperature is achieved using thick-film thermistor inks which are screen printed onto a ceramic substrate of Alumina. This key patented technology was invented in-house within EMC Technology, one of Smiths Interconnects’ technology brands.

Tullio Panarello, Vice President and General Manager Fibre Optics and Components at Smiths Interconnect, commented: “The SpaceNXT K2TVA Thermopad® series is Smiths Interconnect’s response to the increasing demand for high-reliability connectivity in commercial space programs, particularly GEO/MEO and LEO satellites. K2TVA is the newest addition to the SpaceNXT family, an overarching initiative aimed at providing a broad range of readily accessible space qualified COTS+ products for next generation space applications”.

“Our reliable and durable SpaceNXT K2TVA Thermopad® attenuators help customers reach higher frequencies in the face of congestion in broadcast spectrums for wireless communications and when in orbit for communication satellites. They push the boundaries of Size, Weight and Power in a cost effective, easy to implement solution suitable for a wide array of space and defence applications.” added Eric Lakin, Vice President Finance and Strategy.

SpaceNXTTM K2TVA Thermopad® offers the following benefits:

- Each product is engineered using 3D Electromagnetic Simulation (EM) software to provide excellent TCA targeting. This aids in obtaining the best attenuation flatness and Voltage Standing-Wave Ratio (VSWR) within the specified frequency band.

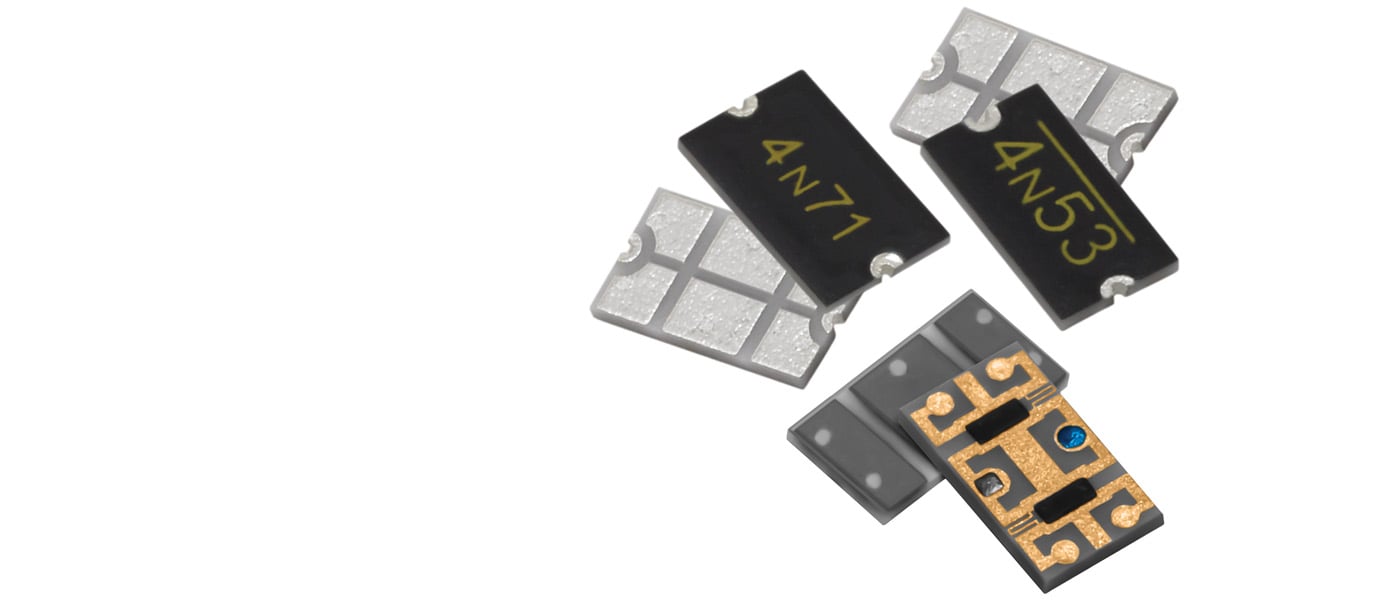

- The Thermopad® can be used in place of a standard chip attenuator to combine level setting or buffering and temperature compensation in a single chip design. This reduces the component count, whilst increasing reliability and lowering costs.

- Using robust proven thick film process technology on an alumina substrate provides a product suitable for applications in harsh environment.

- The Temperature Coefficient of Attenuation (TCA) is up to four times over the original KTVA series, allowing RF designers even more precise temperature compensation.

- Multiple attenuation values, temperature shift options and mounting configurations are available to support both surface mount and wire bond applications.