- Configurable design, large tooling catalog, molding, machining, 3D printing, and assembly automation deliver best-in-class quality, price, and lead times.

- An extensive catalog of standard components provides field-tested designs.

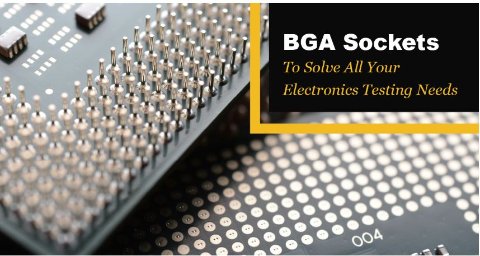

- Double-latching clamshell provides ease of use during operation for high pin count applications.

- Thermal and electrical simulation, Monte Carlo and FEA all ensure the delivery of out-of-the-box solution.

Feature Options

- Spring loaded plunger

- Heat sink

- HAST venting features

- Integrated thermal control with heater and sensor

- Reverse seating plane

- Maximum component clearance under the DUT

- High temperature materials for above 200 °C applications