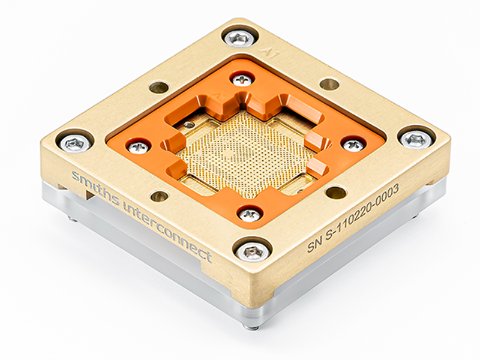

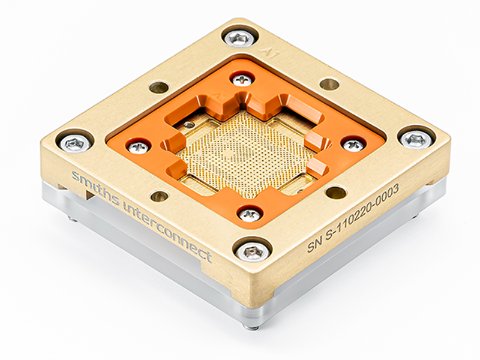

Features

- Spring probe technology using homogenous alloy

- Short signal path 2.85 mm Test Height

- Impedance tuning, can match system or defined as needed, 40, 45, 50 Ohm impedance (single ended)

- Cross-talk suppression IM housing

- Tri-temp socket design to support -40 °C to +125 °C

- Consistent stable contact resistance 120 mΩ (Ave)

- Designed for manual test, bench test, and HVM Production Test using the same socket

- Solution for BGA, LGA, QFN, DFN, and other variants, ideal for minimum pitch 0.35 mm

- Floating base or Hi Low configuration to protect spring probes during use

Benefits

- Tested to 500K

- Short contact path for excellent DC performance

- RF Bandwidth up to 30 GHz @ -1dB IL

- Reduction in pin-to-pin noise (cross-talk)

- Precision-machined socket housing ensures robust mechanical performance

- Field repairable, replace a single probe or full array without the need for additional training

- Patented Insulated Metal socket housing for optimal signal integrity performance and strength

- Match existing PCB socket footprint and test hardware led to cost-saving for customers