Smiths Interconnect's HCS contact (Hyperboloid Contact Stamped) is the evolution of the machined Hypertac® hyperboloid contact technology that is ideal for higher volume applications requiring a fully automated process.

The demand for lower cost hyperboloid contacts led Smiths Interconnect to the development of the stamped/rolled HCS contact, which is supplied on a reel and features an open crimp barrel design.

Features and Benefits:

- Interchangeable and intermateable with screw machined Hypertac®

- Reduced assembly time

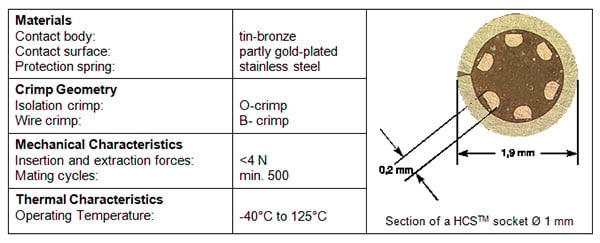

- High reliability B-crimp for the conductor and O-crimp for insulation

The System

For all variations, the wire cage has the same design characteristics. In the contact area all single contact flaps are made in a circle shape which guarantees “wire quality”.

The HCS contacts, on reels for crimping machines with automatic feeder lines are fully compatible with our turned HYPERTAC® hyperboloid contacts. They are available in Ø 0.8/1.0/2.0 mm.

Smiths Interconnect offers hand crimp tools and positioners for field installation of our crimp contacts.

Specifications

Electrical Load

Derating curve 100% acc. to DIN IEC 512/T3 (in air)

Vibration test acc. to DIN EN 60512/item4, 35g X/Y/Z sinusoidal for 50h each, without contact interrupts and without any change in contact resistance [<5mOhm]