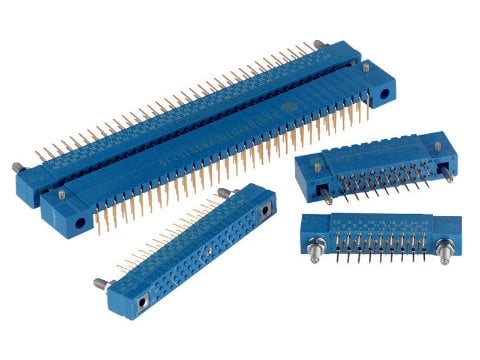

- Featuring Hypertac® Hyperboloid contact technology.

- Mating and unmating cycle life up to 5.000 cycles.

- Available in 2 & 3 row series from 17 and 160 contacts.

- 0.100” (2.54 mm) on center (adjacent rows offset by 0.050” (1.27 mm) to allow straight printed circuit traces).

- Straight dip, right angle solder, crimp, solder cup and Wire Wrap® terminations.

- 0.024” (0.60 mm) diameter pins/sockets rated at 5 Amps.

- Reinforced gold plating: 1,27 µm on active parts.

- Average insertion/extraction force of < 30 g per contact.

- Contacts removable from wiring side (front release, rear removable).

- Alignment and keying provided by the end guides - 36 combinations (user changeable).

- Contact resistance less than or equal to 8 mΩ.

- Male or female contacts and guides available in either plug or receptacle.

- Immunity to shock and vibration fretting.

- Reinforced final production tests.

KN series ESCC3401/016 & ESCC3401/17 compliant connectors come in 2 - 3 row configurations designed with the legendary Hypertac® Hyperboloïd Technology. They were designed as high reliability printed circuit board connectors Specific ESA qualified offering pin counts from 17 to 160 contacts which are widely used in space applications.