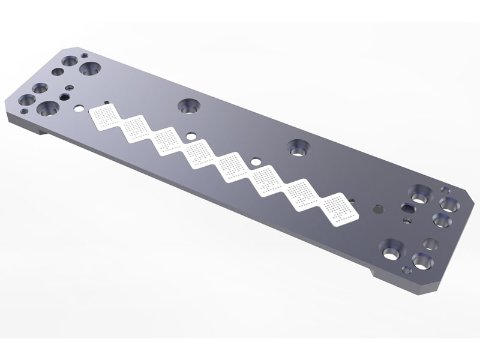

Fixed attenuators are available in 0.1 to 400 W versions, covering DC to 50 GHz applications and offered in 0 to 30dB values. Our attenuators are available in several package styles including chip, tab & cover, flange and coaxial models for use in both low and high power applications. These products are available in standard commercial product as well as high reliability versions.

- Substrates - BeO, AlN, and Alumina

- Commercial and High Reliability Product Lines

- Frequency Range from DC to 50 GHz

- Attenuation Values from 0 to 30dB

- Space and Military Qualified

- Surface Mount, Wire-Bondable and Coaxial Configurations

?ext=.jpg&width=480&resizemode=force)