- Design flexibility, in-house tooling and molds allow for lowest cost of test.

- Extensive catalog of standard components reduces cost and lead-time.

- ≥0.3 pitch accommodates a wide variety of application needs.

- Optimized thermal profile to end-use specification

Feature options

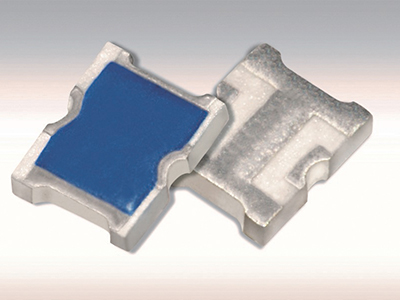

- LCC,QFP, , QFN, LGA, BGA, and WLCSP

- Spring-loaded plunger

- Heat sink

- HAST venting features

- Integrated thermal control with heater and sensor

- Reverse seating plane

- Package inserts for a variety of sizes

- High temperature materials for above 200 °C applications

Utilizing the H-Pin in the C-Series socket provides market leading electrical performance for all reliability testing requirements. The modularity provides unmatched design flexibility and ensures no sacrifices are made in delivering a complete solution without compromising performance or reliability.