- Industry-proven design, in-house tooling, molding, and machining, with 100% automated assembly.

- Extensive catalog of components, configurable options

- Zero-marking lid actuation contributes to higher yields.

- Market-leading electrical performance

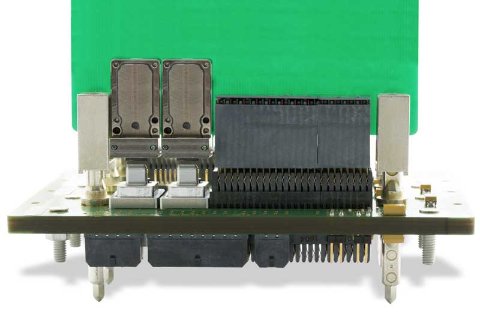

Feature options

- Vertical pressure platen

- Heat sink

- HAST venting features

- Integrated thermal control with heater and sensor

- Reverse seating plane

- Max component clearance under the DUT

- 2 or 3 plate systems

- High temperature materials for above 200°C applications

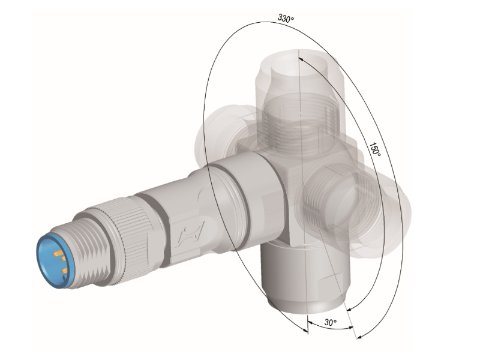

This socket also uses the H-Pin contact technology providing wide RF performance capabilities and exceptional DC characteristics. The K-Series socket checks all the boxes: high frequency, high current, high temperature, low inductance, and Low loss. These features contribute to lower the cost of tests.