The MicroClip ferrule design has proven it can withstand a 1 kg live traffic fiber pull test on a 12-fiber ribbon cable pigtail mated to its LightABLE™ products (40G SR4 and 120G SR12), without any signal performance degradation. This result exceeds by a factor of 2 the requirements of Telecordia GR-468-CORE Fiber Integrity Side Pull Test and confirms the reliability of the fiber ribbon interface with the LightABLE and its MicroClip ferrule.

- Pull force: 1 kg (twice the Telecordia GR-468 requirements)

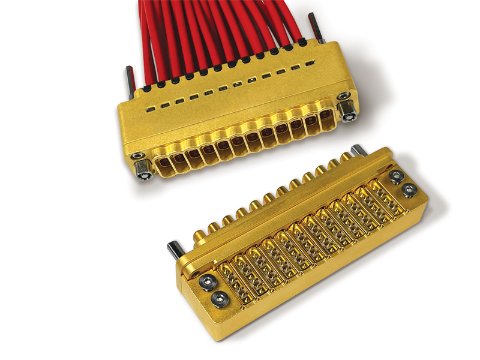

- Lightweight, low profile, and simple assembly

Installation of microclip mt ferrule

Removal of microclip mt ferrule

Close-up

Optical connection with MicroClip