70 Results

-

04 Sep

04 SepDaVinci 112 Test Socket: A Game-Changer in High-Speed Chip Testing

The DaVinci 112 is specifically engineered to handle the advanced requirements of today's most dynamic markets, including Cloud Computing, Data Centers, Artificial Intelligence, and Connected Automotive.

-

12 Aug

12 AugTransforming new product development with "CAD-to-FAB"

The impressive outcome of the trial not only attracted a major new contract, but also match-funding from the UK Space Agency that’s now enabling the establishment of a £3.8m single-site CAD-to-FAB facility in Dundee.

-

24 Jun

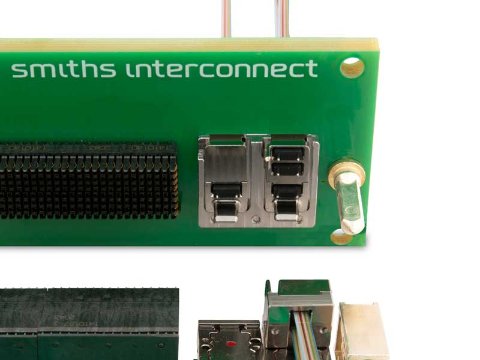

24 JunAn introduction to Smiths Interconnect in Dundee

Smiths Interconnect is one of Smiths Group’s four businesses. We have a truly global reach, with sites in locations around the world including Mexico, Italy, North America, China, and the UK.

-

08 Apr

08 AprAccelerating Connectivity: Exploring High-Speed Data Connectors with Smiths Interconnect

As our world becomes increasingly interconnected, the demand for faster and more reliable connectivity solutions continues to surge. Enter high-speed data connectors – the unsung heroes powering the backbone of our digital infrastructure.

-

13 Mar

13 MarUnderstanding RF Filter requirements for mission critical applications

In the space and defense industry, the requirements for RF filters are stringent due to the demanding environments and critical applications they serve. RF filters are commonly used in space and defense applications for several reasons.

-

04 Mar

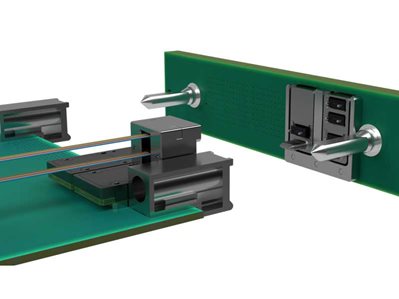

04 MarElevating Connectivity: Exploring the Versatility of Smiths Interconnect's Backplane Connectors

To meet the demands of mission-critical applications, Smiths Interconnect offers a comprehensive range of backplane connectors, known for their performance and reliability.

-

26 Feb

26 FebA Costa Rican plant for advanced component manufacturing

The electronic system development supply chain that has become increasingly diverse and global, with components provided from various regions around the world. This comes with several challenges including variability in supply and demand, geopolitical tensions and unforeseen events that may lead to delays, increased costs and supply chain inefficiencies.

-

08 Feb

08 FebConnectors for digital mining operating in arduous environmental conditions and for extreme applications

The mine of the future is being built on connectivity of data and automation. The benefits of Industry 4.0 through digitalization of data from connected assets in the mining industry is profound. To enable near-real time decision, a digital mine needs to bring together data from across its assets distributed within its value chain. If done correctly, it rewards the industry with increasing uptime of critical assets, reducing costs and operational risks.

-

05 Feb

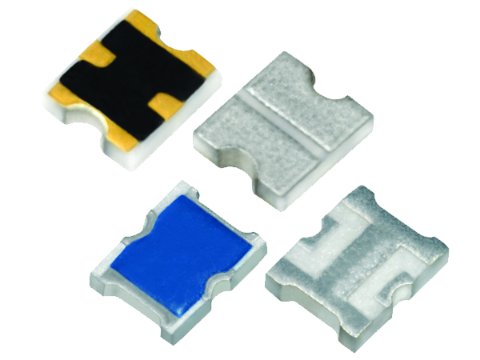

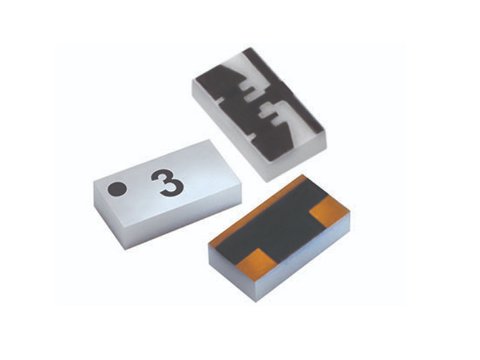

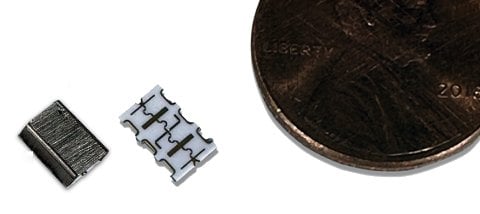

05 FebMaking Sense of High-Reliability Radio Frequency (RF ) Components

HR TSX Series represents a significant leap forward in the realm of high-frequency surface mount chip attenuators. Its combination of small form factor, robust construction, and versatile performance make it an attractive choice for space and defense applications.

-

10 Jan

10 JanRevolutionizing Space Component Engineering: Smiths Interconnect's Space Qualification and Rapid Engineering Laboratory

The space qualification laboratory plays a pivotal role in simulating the harsh conditions of space, ensuring the quality and durability of space components.

-

11 Dec

11 DecMastering connectivity challenges: exploring the strengths of the C9394 Series PCB Connectors

Central to the C9394 Series is its outstanding capacity, boasting an impressive 450 ways per module. This high-density design allows engineers and manufacturers to optimize space on printed circuit boards (PCBs) without compromising performance.

-

04 Dec

04 DecElectrophysiology applications: when medical connectivity pushes the boundaries of size

In the realm of medical technology, where precision and innovation intersect, the quest for excellence becomes an unyielding pursuit. When dealing with the design of interconnect systems for the medical industry, the level of engineering attention and engagement required to develop a top performance product is very high.

-

27 Nov

27 NovFAQs at Smiths Interconnect: test sockets, capabilities, and support

After over 40 years of industry experience, Plastronics was acquired by Smiths Interconnect as the company’s one-stop shop for burn-in and reliability testing. As the complementary in-house burn-in division, we have also brought a wealth of knowledge and expertise in socket design and manufacturing.

-

13 Nov

13 NovSpaceNXT Series: Elevating Space Connectivity with Pre-Tested & Qualified Interconnects

Smiths Interconnect recognizes the critical importance of connectivity in the realm of space technology and is proud to present the SpaceNXT™ Range - a groundbreaking initiative that offers pre-tested and qualified interconnect solutions for the next generation of space applications.

-

01 Nov

01 NovWhat is thermal simulation and why is it important to reliability burn-in testing?

Not every semiconductor manufacturer utilizes thermal simulation in their reliability testing setup. Lower power burn-in allows for an acceptable temperature rise within the package/die in a traditional burn-in chamber running at 125°C. As packages in burn-in are moving to higher power output, socket and burn-in systems may need to have enhanced features to manage the desired target die temps.

-

23 Oct

23 OctProbe Life – Board Test Probes: A Comprehensive Guide

To extend the life of your probes and lower the overall cost of testing, consider the following steps.

-

10 Oct

10 OctFixed Attenuators: Ensuring Reliability and Durability

In the realms of space exploration and defense technology, electronic components play a pivotal role in ensuring mission success and national security. Among these components, fixed attenuators stand out as essential tools for signal management, maintaining the integrity of electronic systems amidst the most challenging environments

-

04 Oct

04 OctRevolutionizing Medical Devices with High-Density D04 Connectors

With the growing popularity of portable and patient-wearable devices, the size and weight of connectors have suddenly taken center stage in the medical sector.

-

.jpg?ext=.jpg&width=480&resizemode=force) 19 Sep

19 SepExploring the Cutting-Edge SpaceABLE® Radiation-Resistant Embedded Optical Transceivers

Space missions expose electronic components to intense radiation, a challenge that can compromise the functionality of conventional devices. However, Smiths Interconnect's SpaceABLE® line of products is purposefully designed to withstand these extreme conditions.

-

01 Sep

01 SepOptimizing Production Test of QFN-packaged IC’s for Consumer, Automotive, Industrial and Power Applications.

Where best-in-class electrical requirements intersect with a need for a small outline, low-profile footprint, IC designers are increasingly migrating to QFN packages. Meeting these testing challenges requires a test socket solution that is robust, reliable, and electrically “clean.”

-

07 Aug

07 AugImproving time- and cost- efficiency in reliability burn-in testing

When companies develop new devices, they must ensure there are no failures in the field. This means that thorough reliability burn-in testing must take place from the start to avoid malfunctions down the road.

-

14 Jul

14 JulAre X-Band Lowpass RF Filters right for you?

The X-Band cutoff frequency range is from 8 GHz to 12 GHz with a wavelength of 3.8 to 2.5 cm.

-

21 Jun

21 JunHigh-Power Burn-In Testing in 2023: How to Overcome the Extreme

The tech zeitgeist is all about the extreme. The more advanced our devices become by the day, the more they evolve – and consumers’ expectations with them.

-

08 May

08 MayOne-stop-shop laboratory replicates deep space environment

Space flight hardware is exposed to severe shock, vibration, thermal variations and electromagnetic environments that start with launch and continue throughout its operational lifetime. Environmental tests expose the hardware to these environments in a simulation laboratory to validate the design, screen for manufacturing defects and ensure the reliability and survivability of flight hardware.

-

?ext=.jpg&width=480&resizemode=force) 01 May

01 MayRaising the Bar of Burn-In Testing Sockets

Burn-in testing is widely used as an aid in producing failure-free electronic components. When scientifically planned and conducted, burn-in-testing sockets offer one of the most effective methods of reliability screening at the component level. Testing during production plays a vital role in ensuring reliability and repeatability. Semiconductor manufacturing plants perform tests at each stage of production to eliminate defective parts as early as possible while precisely controlling each process parameter of the chip.

-

24 Apr

24 AprMission Critical: Maintain your RF cables and connectors

Guidelines for maintaining cables and connectors.

-

05 Apr

05 AprRethinking Blind Mate Connectors to Increase Reliability in Miniaturized Electronics Assembly

Creating more compact electronic components with higher functionality is a challenge for all electronics manufacturers. Whatever industry you're in, creating consumer, business, or military-grade electronics, the challenge presents itself, and the stakes are high. As electronics are expected to continue shrinking while increasing capabilities, blind mating connectors are required to meet those same size and functionality requirements.

-

03 Apr

03 AprMiniature Coaxial Isolators and Circulators

A coaxial circulator is a passive, non-reciprocal three-port device that allows microwave or radio-frequency signal to exit through the port directly after the one it entered. An isolator is a two-port device that transmits microwave or radio frequency power in one direction only, while the other direction is blocked. Isolators can be considered as a special case of circulators and are made by suitably terminating one port of the circulator ports.

-

13 Mar

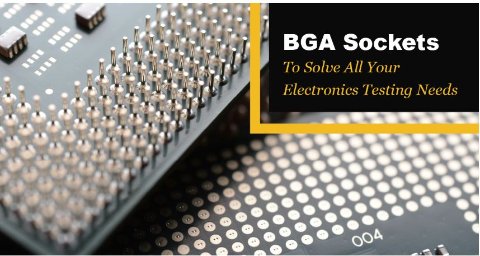

13 MarBGA Sockets To Solve All Your Electronics Testing Needs

Plastronics, a Smiths Interconnect technology brand, is a global provider of innovation for semiconductor reliability testing, meeting the industry’s burn-in socket needs for more than 40 years. It all started when our company invented the first open-top, application-specific socket for production burn-in of LCC packages. This innovation helped semiconductor manufacturers significantly increase their throughput and decrease costs.

-

14 Feb

14 FebChallenges Semiconductor Package Size and Pitch Face in Shrinking Consumer Electronics

Tiny computers, smartphones, and small electronic devices that industry leaders and other companies have popularized are forcing the hand of semiconductor package designers to shrink the package to fit within these little hand-held gadgets. The demand for technology applications, such as smart homes, smart manufacturing, smart medical care, and automotive electronics, continues to increase. At the same time, the requirements of continuous miniaturization and functional diversification of electronic product demands also increase.

-

03 Jan

03 JanMeeting the increasing demand for rugged, high-speed connections in Space applications.

Space satellites market is evolving from RF Analog-based payloads providing low speed telecommunication signaling, to a new Digital Transparent Processor architecture for high throughput satellites. This type of architecture increases the demand for rugged and higher speed connectivity.

-

02 Dec

02 DecAutoclaving for Medical Devices

Autoclaving is often used to sterilize medical devices to prevent disease transmission both in new and reusable products. Autoclaves sterilize by introducing high pressure steam into a chamber containing the objects to be sterilized. Therefore, these devices must be able to withstand autoclaving temperatures in the range of 135°C without damage, deformation, or disintegration.

-

07 Nov

07 NovSpring Probe based Pin Grid Arrays (PGAs) for MRI Applications

Spring probes offer high density and have a very high mating cycle life, often higher than traditional pin & socket contact systems, and this is needed to keep very expensive MRI systems operating to their full capacity and patient throughput to a maximum.

-

01 Nov

01 NovEnsure Reliability in Edge Computing with Burn-In Testing

Retail. Manufacturing. Government. Healthcare. Distribution. Choose an industry, and edge computing is there helping organizations thrive. Every industry has more data to generate, control, share, and save, which means that through 2022 and beyond, more enterprises will use the edge to benefit their business.

-

20 Oct

20 OctCustomizable modular connectors for demanding therapeutic devices

Modern therapeutic systems for the treatment of weight loss for both health and aesthetic purposes are evolving to help people live a better life. To achieve the necessary results, medical devices need to ensure long-lasting, constant and high-level performance with reliable components able to support harsh conditions.

-

10 Oct

10 OctThe next step in optical interconnectivity for the defense industry

Optical interconnectivity has a significant impact on the defense industry. Not only does it allow greater amounts of data to be passed over longer distances, but it also minimizes SWaP (size, weight, and power) relative to copper alternatives. In fact, cabling weight can be reduced more than 90% with no interference and carry high-speed data 15 to 20 times further.

-

29 Sep

29 SepPhase stable cable assemblies: reliability where it’s needed most

From military aircraft to radar applications to satellite communication links, we rely on cable assemblies to transmit signals between multiple devices, internally in a single device, or as part of testing processes.

-

05 Sep

05 SepCustom Connectors VS Catalog Connectors: Benefit Breakdown and Challenges

There's no escaping the expectations to create more compact electronic components with higher functionality. Designing shrinking electronics is a challenge for all electronics manufacturers. Whatever industry you're in and no matter if you’re creating consumer, business, or military-grade electronics, there is a demand for building smaller, smarter, and sturdier electronics.

-

23 Aug

23 AugSmall but mighty: How attenuators benefit defense and space industries

Current space and defense industries are putting pressure on electronic manufacturers to deliver high performance with smaller form factor. For applications in these industries, from radios to drones and satellites, miniaturizing components such as RF chip attenuators with broad frequency ranges is becoming critical for developing technology and meeting the challenging demands of defense and space applications.

-

08 Aug

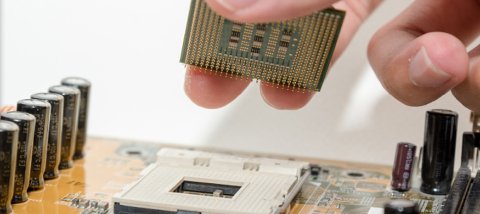

08 AugIs it really that hard to improve chip test performance?

In the digital era, semiconductor chips are present in almost every aspect of our lives. Whether it is from microwave ovens to computers, cell phones, computer central processing units, and other electronic devices there are a variety of chips installed.

-

20 Jul

20 JulHow to select the right electrical connector for specific medical devices and applications

To ensure patient and provider safety, medical connectors must satisfy a variety of government and industry standards depending on the usage and specific applications.

-

06 Jun

06 JunHow connectivity can play a key role in rail braking systems

Train deceleration is a key function that implies passengers’ safety, environment and property protection and nothing can be left to chance or neglected when it is the moment to select the right parts that have to compose the brake system. With this in mind, the design engineers have to pay attention to reduce the overall maintenance costs as well to provide a dependable and market aligned solution.

-

18 May

18 MayHigh five for new HBB circular connectors

Smiths Interconnect’s new HBB five-pole connector packs flexibility, reliability and safety as well as power into one easy-to-use connector for demanding applications. We’ve built an international reputation on our ability to anticipate customers’ future needs and innovate to meet them. In the defense sector, we’ve been exploring the potential of the energy revolution for combat vehicles, both on the ground and in the air.

-

26 Apr

26 AprEnhanced ratings for KA connectors

Our popular KA Series PCB connectors are capable of performing to significantly higher levels than the conservative ratings to date might suggest.

-

24 Feb

24 FebCavity filter technology can support aviation devices with radar altimeter interference

The recent rollout of the 5G C-band frequencies has caused concerns for radar altimeter interference in avionic systems—including commercial transport, business, regional, and general aviation airplanes and helicopters.